The carriage is equipped with a refrigeration unit, oil heating device, and the temperature is controlled to be pre-warmed at 20-26 °C before loading the seedlings. The temperature of the seedlings is controlled at 22-26ºC.

The carriage is equipped with a refrigeration unit, oil heating device, and the temperature is controlled to be pre-warmed at 20-26 °C before loading the seedlings. The temperature of the seedlings is controlled at 22-26ºC.

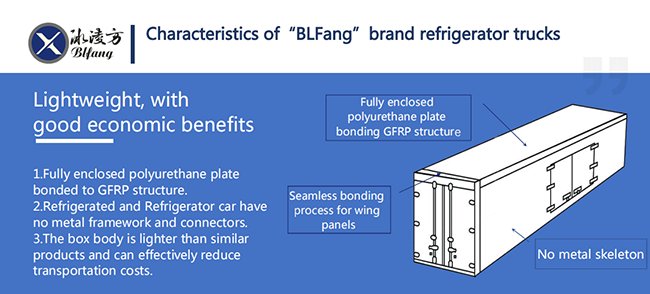

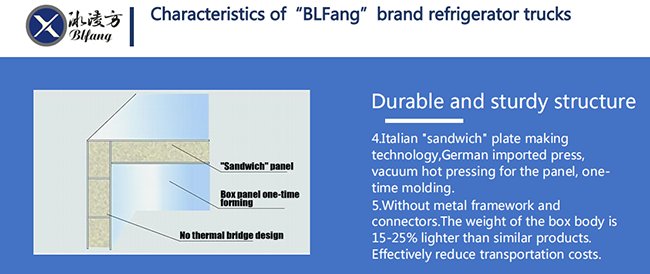

Introduction to the box structure of the chicken seedling transport vehicle:

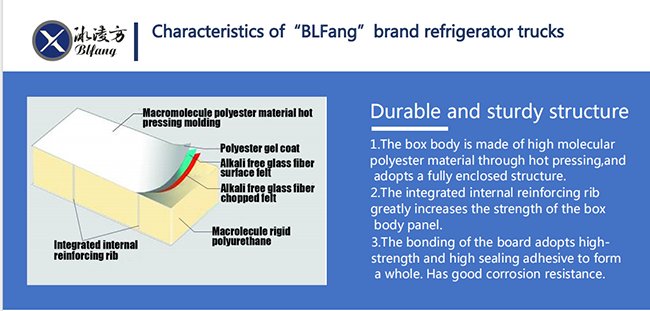

the box body is an internal and external FRP structure, and the middle is 8cm thick polyurethane insulation material, which has excellent insulation performance. The number of louvers can be reasonably installed on the left and right sides of the vehicle according to the size of the vehicle model. Louvers can also be installed on the front and back of the box body as required (optional), and high-power exhaust fans are installed on the top of the vehicle, It can effectively alleviate the indoor air quality and ensure the survival rate of chicken, duck and goose seedlings in long-distance transportation. The most important thing is that the box is equipped with a temperature control system, which can comprehensively adjust the temperature in all corners of the carriage, truly achieve the constant temperature effect, create a comfortable living environment for chicken, duck and goose seedlings to the greatest extent, ensure the survival rate of chicken, duck and goose seedlings, and bid farewell to the previous pure truck transportation, It will bring more and greater benefits to breeding enterprises. It is your preferred chicken seedling transport vehicle, goose seedling transport vehicle and duck seedling transport vehicle to get rich.

the internal temperature of the refrigerated body(within) It is composed of a vehicle-mounted cooling and heating integrated machine and two air mixing air ducts on both sides to realize the circulation of air in the living space of poultry seedlings. And a geothermal ventilation system is installed under the floor. For transportation of one day chicks, maintaining the internal temperature of the van body.

Body structure and Insulation inner plate: fiber glass

out plate: fiber glass

keep warm material :8mm polyurethane foam

80mm thickness for side and top, 90mm thickness for bottom

All walls and roof panels (internal and external), sub-frames, main-frames and chassis are anti-corrosive treated

Fiberglass body with anodized aluminum profile sheathing

The body has drains for release of water

Body structure is rigid and capable of withstanding vibrations and shocks from rough roads while keeping the load fully secured when the vehicle is fully loaded.

Door and exhaust fan Body with two insulated doors at the rear for full width opening. At least two hinges per door. Hinges and closing mechanism is of a robust design.

Equipped with an array of high-power exhaust fans, a manual door for skylights, and several shutters on the front and side panels.

Optional Electricity supply system for vehicles packing in high-temperature environments, equipped with micro-generators to supply power to related equipment.